Introduction

Inventory management is a fundamental aspect of business operations that involves overseeing the procurement, storage, and distribution of goods. In an era marked by dynamic market conditions, the efficient management of inventory becomes paramount for businesses to stay competitive and meet customer demands.

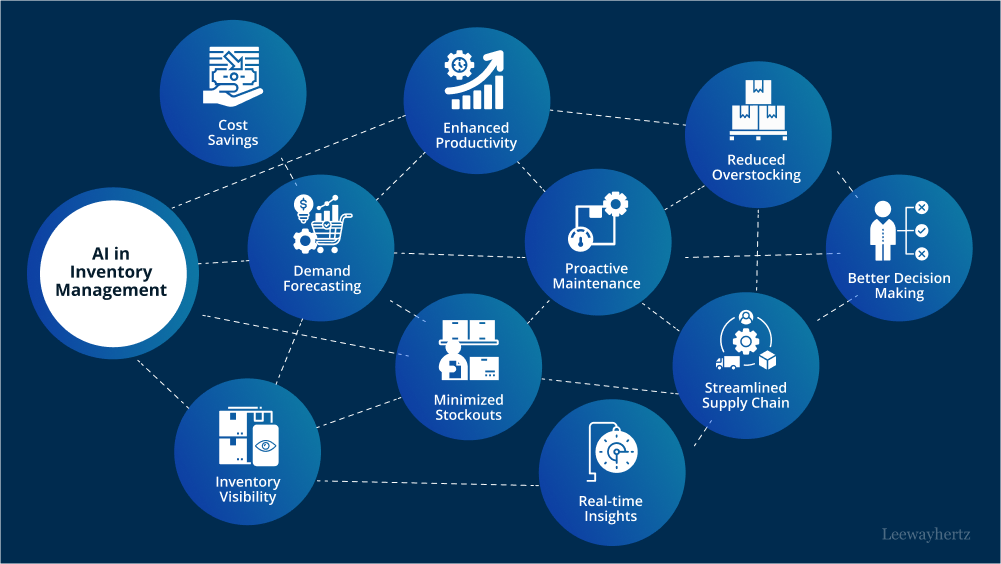

This article provides a comprehensive overview of inventory management, emphasizing the critical importance of efficiency for businesses, particularly with the integration of AI in inventory management.

The Fundamentals of Inventory Management

1. Definition and Scope

Inventory management refers to the systematic control and tracking of a company’s stocked goods. These goods can include raw materials, work-in-progress items, and finished products. The primary goal is to ensure a steady flow of products, meet customer demand, and prevent excess stock or stockouts.

2. Key Components of Inventory Management

2.1 Inventory Planning

Inventory planning involves forecasting demand, setting reorder points, and determining optimal stock levels. This ensures that businesses can align their inventory with anticipated customer requirements.

2.2 Inventory Control

Inventory control focuses on monitoring stock levels, tracking the movement of goods, and implementing strategies to prevent overstocking or stockouts. It aims to strike a balance between supply and demand.

2.3 Inventory Optimization

Inventory optimization aims to maximize the efficiency of inventory management. By minimizing carrying costs, reducing stockouts, and improving overall turnover, businesses can enhance their profitability.

The Significance of Efficient Inventory Management for Businesses

1. Meeting Customer Demand

Efficient inventory management ensures that businesses have the right products available at the right time. This responsiveness to customer demand is crucial for customer satisfaction and loyalty.

2. Minimizing Costs

Optimizing inventory levels helps businesses minimize carrying costs associated with excess stock. At the same time, it prevents the costs associated with stockouts, such as lost sales and rushed shipments.

3. Improving Cash Flow

Effective inventory management contributes to improved cash flow by freeing up capital that would otherwise be tied up in excess inventory. This liquidity is vital for business operations and strategic investments.

4. Enhancing Operational Efficiency

Streamlining warehouse operations and maintaining optimal inventory levels contribute to operational efficiency. It reduces the risk of errors, enhances productivity, and ensures a smooth flow of goods throughout the supply chain.

5. Gaining Competitive Advantage

Businesses with efficient inventory management practices can respond more swiftly to market changes. This agility provides a competitive advantage by enabling faster adaptation to evolving customer preferences and industry trends.

The Role of Artificial Intelligence (AI) in Inventory Management

1. AI in Demand Forecasting

1.1 The Challenge

Traditional demand forecasting methods often rely on historical data and may struggle to adapt to dynamic market conditions and sudden shifts in consumer behavior.

1.2 AI Solution

AI revolutionizes demand forecasting by leveraging machine learning algorithms. These algorithms analyze vast datasets, market trends, and external factors to predict future demand more accurately. The self-learning capabilities of AI enable continuous refinement of forecasts, ensuring adaptability to changing market dynamics.

2. AI in Inventory Optimization

2.1 The Challenge

Determining optimal inventory levels involves considering various factors such as lead times, supplier performance, and carrying costs. Traditional methods may fall short in optimizing these variables simultaneously.

2.2 AI Solution

AI-driven optimization algorithms excel in determining optimal inventory levels. By considering multiple variables simultaneously, these algorithms ensure that resources are allocated optimally, minimizing idle time and reducing overall production costs. The adaptability of AI allows for quick adjustments to unforeseen disruptions, ensuring a consistently optimized inventory.

3. AI for Predictive Maintenance

3.1 The Challenge

Unplanned equipment downtime can be a significant challenge in inventory management, leading to production delays and increased maintenance costs.

3.2 AI Solution

AI in inventory management incorporates predictive maintenance by analyzing data from sensors and IoT devices. By predicting when equipment is likely to fail, businesses can schedule maintenance proactively, reducing downtime, extending equipment lifespan, and minimizing maintenance costs.

4. AI in Supply Chain Optimization

4.1 The Challenge

Managing a complex supply chain involves coordinating various processes, from sourcing raw materials to delivering finished products. Traditional methods may struggle to optimize the entire supply chain efficiently.

4.2 AI Solution

AI analyzes data from various sources, including suppliers, warehouses, and transportation networks, to optimize the entire supply chain. This includes identifying bottlenecks, optimizing routes, and minimizing transportation costs to ensure efficient inventory flow.

5. AI-Enabled Real-Time Analytics

5.1 The Challenge

Real-time monitoring of inventory levels, sales trends, and supply chain activities is crucial for timely decision-making. Traditional methods may not provide the speed and accuracy required.

5.2 AI Solution

AI enables real-time analytics by continuously analyzing inventory data and providing insights into current conditions. This allows businesses to make informed decisions quickly, such as adjusting inventory levels, reallocating resources, or rerouting shipments, to respond to changing market conditions.

Case Studies: Success Stories of AI in Inventory Management

1. Amazon

Amazon, a global e-commerce giant, leverages AI algorithms for demand forecasting and inventory optimization. The use of AI-driven predictive analytics ensures that products are available for customers when needed, minimizing stockouts and maximizing customer satisfaction.

2. Walmart

Walmart, a retail giant, utilizes AI-powered inventory management systems to optimize its supply chain. By leveraging AI for demand forecasting and inventory optimization, Walmart maintains optimal inventory levels across its stores, minimizing carrying costs and enhancing profitability.

3. Unilever

Unilever, a multinational consumer goods company, employs AI-driven predictive maintenance to optimize its production processes. Proactively addressing maintenance issues through AI ensures the uninterrupted flow of goods through the supply chain, minimizing disruptions and maximizing efficiency.

Future Trends in AI-Enhanced Inventory Management

1. Autonomous Inventory Management Systems

AI-driven autonomous inventory management systems will become increasingly common. These systems will automate inventory processes, reducing the need for manual intervention and ensuring continuous optimization.

2. Blockchain Integration

The integration of AI with blockchain technology will provide transparent and secure supply chains. This will enable real-time tracking of inventory movements, ensuring data integrity and security throughout the supply chain.

3. Robotics and Automation

AI-powered robotics and automation will revolutionize warehouse operations. Businesses will increasingly leverage robotic systems for tasks such as picking, packing, and shipping, reducing labor costs and increasing overall efficiency.

4. Personalized Inventory Management

AI algorithms will enable businesses to personalize inventory management based on individual customer preferences and behaviors. This will ensure that the right products are available to the right customers at the right time, enhancing the overall customer experience.

Conclusion

In conclusion, inventory management stands as a linchpin in the success of businesses, influencing customer satisfaction, operational efficiency, and financial stability. The integration of AI into inventory management processes adds a layer of sophistication, enabling businesses to optimize demand forecasting, inventory levels, maintenance practices, and supply chain operations. As AI continues to evolve, future trends in autonomous inventory management systems, blockchain integration, robotics, and personalized inventory management promise to reshape the landscape further. By embracing these advancements, businesses can not only navigate the complexities of modern markets but also position themselves as agile and responsive players in the ever-evolving realm of inventory management. The synergy of efficient inventory management and AI technologies is undeniably a recipe for sustained success and growth in the competitive business environment.

Leave a comment